Trough/Chute Feeder

Overview:

Chute feeder is widely used in chemical industry, mining, gold treatment, construction, mineral processing, coal and carbon industries, sending the block material from the storage bin to the receiving device.

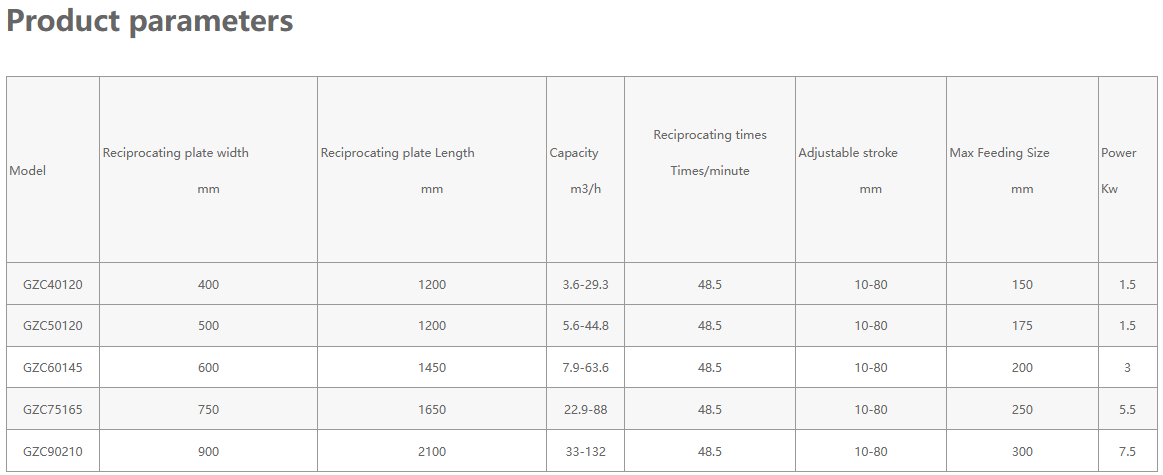

Chute feeder can be erected on the ground, can also be suspended on the discharge port of the mine silo. Slot bottom plate for reciprocating motion, its stroke for 20-60 times / min, stroke for 20-200 mm. stroke can be driven by the device eccentric wheel for appropriate adjustment, eccentric distance for half of the stroke. According to some mineral processing plant production practice, for viscous ores, the eccentric distance should not be less than 30mm. slot feeder trough width is about 2-2.5 times the maximum extent of feeding. The largest trough feeder can meet the less than 500mm particle size iron ore feeding. The most commonly used specification is 980*1240 slot feeder, its feeding size is 350-0mm, suitable for 400*600 jaw crusher feeding equipment.

Working principle:

Chute feeder consists of frame, drag plate (coal feeding chute), rollers and other combinations, when the motor is turned on through the elastic coupling, reducer, linkage mechanism to drag the drag plate on the rollers in a linear reciprocating motion, the material is uniformly discharged to other equipment.